Complete tunneling program

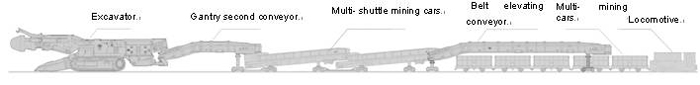

Tunneling Program Solution 1: Full-hydraulic drill jumbo +mining mucking loader + shuttle mining car (group) + belt elevating conveyor +multi-mining trolley + locomotive

Description of the Tunneling Program:

When excavating main tunnel in vertical well, mining mucking loader pulls multi-shuttle mining car and belt elevating conveyor to working surface. The locomotive pushes mining cars onto the rail that is parallel to shuttle mining car. The loader puts gangue into shuttle mining car continuously. Then gangue is dumped into mining cars through belt elevating conveyor. After mining cars are full, the locomotive will take them away. After final gangue is loaded into shuttle mining car, the loader pushes backward shuttle mining car at a certain distance. So working face is ready for next procedure. Gangue from shuttle mining car will be transferred. The whole set of equipment can be used together with full-hydraulic drill jumbo.

The most advanced full-hydraulic mining excavating loader in China is used, which can load gangue quickly and not blind angle. Shuttle mining car is connected with belt elevating conveyor to dump several mining cars continuously. Before mining cars come, shuttle mining car with large amount of storage capacity can store gangue temporarily to balance the job so that drilled footage per month and mechanization level is increased.

Typical Cases:

Shandong Xinwen Mining Group (Suncun Coal mine, Longgu Coal mine and E'zhuang Coal Mine)

Anhui Huaibei Mining Group (Suntong Coal Mine) Shandong Feicheng Mining Group (Liangbaosi Coal Mine)

Shanxi Huozhou Coal Electricity Group (Huipodi Coal Mine)

Construction Company of Hunan Lianshao Construction Group (Luohe Iron Mine)

(Shanxi Xishan Coal and Electricity Power (Malan Coal Mine)

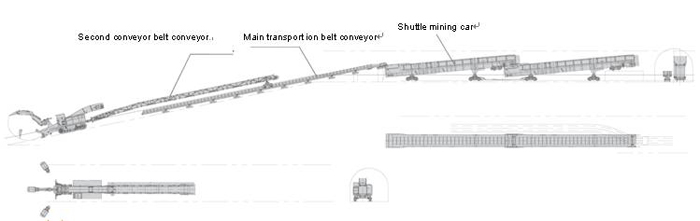

Tunneling Program 2: Full-hydraulic drill jumbo +mining mucking loader + gantry second converyor – telescopic belt conveyor + shuttle mining car (group) + belt elevating conveyor

Road headers + Gantry second converyor + shuttle mining car (group) + gantry loading belt conveyor + multi-mining cars + locomotive

Description of the Tunneling Program:

Mining mucking loader is used with full-hydraulic drill jumbo. In recent years, blasting excavation equipment in rock roadway has been promoted, which loads slag quickly and can be used on full section. Shuttle mining car is used in the program above, which increases excavating efficiency greatly and makes slag-raking machine accomplish the task at a time.

Shuttle mining car in the program above and loading belt conveyor are fixed. Only elastic belt is extended with extension of the roadway. Shuttle mining car and accessory can be arranged in different areas of the roadway flexibly, without shuttle mining car moving, with loading and unloading points fixed which reduces potential risks.

The program below means the whole line moves forward along the tunnel. The whole equipment is flexible and applicable to small section, which can be used in bending tunnel.

Typical cases:

Shanghai Datun Coal and Electricity Power Group (Xuzhuang Coal Mine) Shanxi Xiyang Energy Group (Baiyangling Coal Mine) Anhai Huaibei Mining Group (Taoyuan Coal Mine) Xuzhou Mining

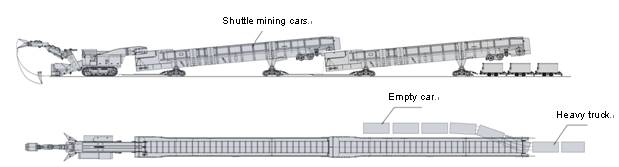

Tunneling Program 3: Mining mucking loader (special for large slope) +second conveyor belt conveyor and third transportation belt conveyor + shuttle mining car + mining car (group)

Description of Tunnel Construction Solution:

This program means mining mucking loader (group) (special for large slope) is used for downhill roadway≤18 in vertical well. Transferring slag is slow and removing slag is limitedl. Therefore, shuttle mining cars is provided for buffering. Slag-raking machine on the front end can run continuously to excavate continuously and quickly. Compared with program 1, it is not necessary to wait for the forward dumping wagon moving back and forth. It has more continuousness and more advantages on roadway.

Typical Cases:

Shandong Yanzhou Coal Mining Group (Dongtan Coal Mine, Jining No. 2 Mine)

Anhui Huaibei Mining Group (Yuandian Coal Mine)

Tunneling Program 4: Mucking loader+ single (multi-) shuttle mining car(s) + multi- mining cars + locomotive

Description of Tunnel Construction Solution:

It is used to excavate main tunnel in vertical well. After blasting of full section, mucking loader pulls shuttle mining car to working surface. First, it loads gangue at 4~5m from working surface, then cleans rail surface. Gangue on both sides of the rail is not loaded temporarily. Now working surface is ready for next procedure. Slag-raking machine (locomotive) pushes shuttle mining cars (group) to car turnout and pushes mining cars onto the bottom of shuttle mining cars to transfer gangue in the cars at a time. After dumping, it moves back to load remaining gangue on working surface. Belt loader is not required in this program, which is simpler. But the whole equipment is required to move back and forth. Therefore working procedure is complicated and labor is intensive.

Typical cases fotr this solution:

Shandong Yanzhou Coal Mining Group (Dongtan Coal Mine, Zhaolou Coal Mine)

Anhui Hengyuan Coal and Electricity Power (Wugou Mine, Wolonghu Mine)

Xuzhou Mining Group (Jiahe Coal Mine)