Underground Mine Solution

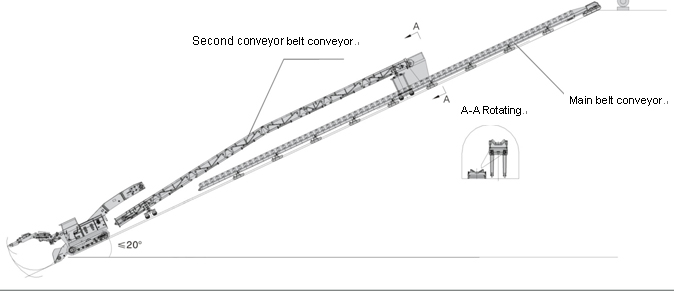

Program 7: Mining mucking loader (special for large slope) + Side dumping belt conveyor+ fixed belt conveyor + traction winch

Description of the Underground Mine Solution:

This program is applicable to long roadway and slope< 20º. Mucking loader (special for large slope) is used to excavate and pick up slag. Then slag is loaded through second transportation belt and transported through main belt conveyor. When blasting, the double-purpose belt is pulled up against traction winch on the ground. When placing material cars, second transportation belt is against the rear part of mining mucking loader. This program is mainly used for permanent belt laid at one time and roadways on permanent rail. It has advantages such as quick and continuous withdrawal of slag.

Typical cases of this Underground Mine Solution:

Guizhou Shuicheng Coal Mining Group (Mayang Coal Mine, Dawan Coal Mine)

Guizhou Qianxi (Wenhua Coal Mine, Jinxiang Coal Mine)

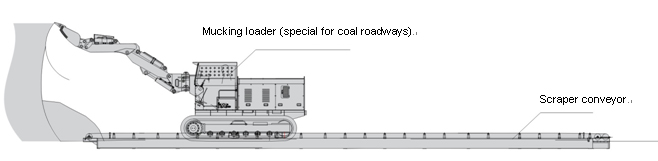

Program 8: Mucking loader (special for coal roadways) + scraper conveyor

Description of the Underground Mine Solution:

This program is applied to coal roadways and half coal roadways in room and pillar mining. This program uses mucking loader (special for coal roadways) and scraper conveyor designed by our company. For soft coal seam, the bucket can be used for coal mining. For hard coal seam, breaking hammer on the mining mucking loader as well as the bucket can be used. At the same time, blasting method is also applicable. The advantages include less investment, less dust, high efficiency and low labor intensity.

Typical case of the Underground Mine Solution:

Hebi Zhongtai Mining Co., Ltd

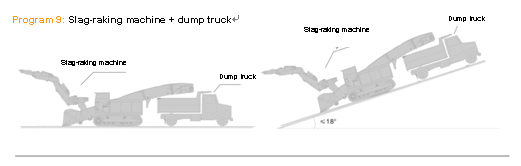

Program 9: Slag-raking machine + dump truck

Description:

It is common in main tunnel for non-coal mine. The roadway is relatively short, trackless removal is used. Traditional slag-raking machine is tunneled by diesel power. In addition, heavy smoke exists in the coal gangway after the dump truck exhausts, which leads to impossibility to work or harsh environment. In this program, electric mucking loader and dump truck are used together, which reduces smoke greatly, improves the environment in the gangway and working efficiency greatly.

Typical cases:

Jiangxi Xiushui Xianglushan Tungsten Co., LTD (Wukengkou Mine)

Wenjian Group (Anhui Dacangzhuang Project Department)

Liaoning Angang Mine Construction Co., LTD

Shougang Mining Co., LTD (Huaye Project)

Yunnan Shangri-La (Hongxin Copper Mine)

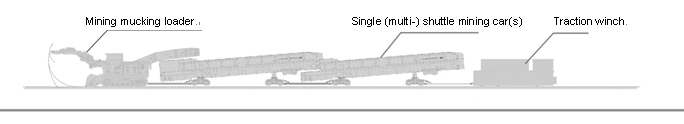

Program 10: Mining mucking loader+ single (multi-) shuttle mining car(s) + traction winch

Description:

This program is common in main tunnel for underground mine, metal and non-metal mine. Gangway development is belong to general program It is applicable for both large and small sections. After full-section blasting, mining mucking loader with quick loading slag and shuttle mining cars with large volume are used together. Car turnout is provided at a certain distance for circulating slagging.

Typical cases:

Main gangway for Guizhou Zunyi Miaoxin Coal Mine

Yunnan Yunnan Shangri-La Copper Mine

Sichuan Xingwen Fudiyuan Coal Mine

Sichuan Xinwen Xinlong Coal Mine

Nantong Coal Mine (Miaoxin Coal Mine, Guancang Coal Mine)

Guangxi Xishan Mining Co., Ltd

Shangxi Xishan Xishan Coal and Electricity Power (Dongqu Coal Mine)

Chuannan Construction Engineering (Shiping No.1 Mine)