Case of Complete Tunneling Program

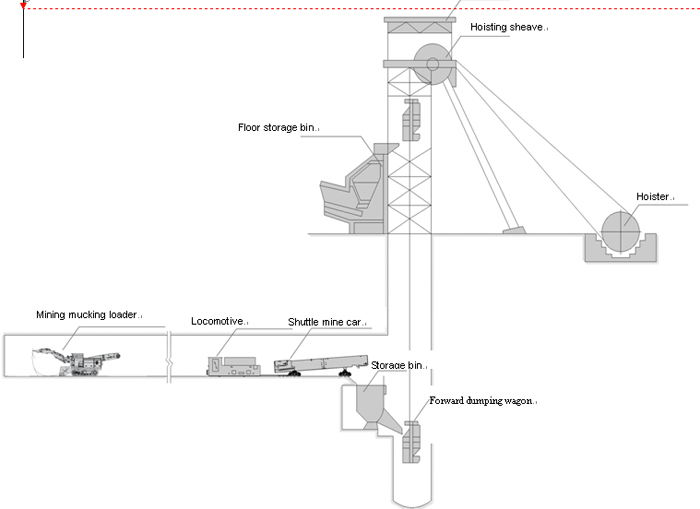

Program 18: Locomotive + shuttle mining car+ Forward dumping wagon

Description:

The main tunnel is developed under the vertical shaft; the shuttle mining car matched with the mucking loader is adopted in the gangway; after the shuttle mining cars unload the slag into the forward dumping wagon, the forward dumping wagon is lifted. By the reasonable matching, the working efficiency is improved while the mechanized operation level is promoted.

Typical case:

Xinjiang Lli (Hazi Gold Mine)

Shanxi Tongmei Group (Dongzhouyao Coal Mine)

Xinjiang Non-ferrous Gold Group (Kalasake Copper Mine)

Case Analysis One: Dongtan Coal Mine of Yanzhou Coal Mining Group

Dongtan Coal Mine of Yanzhou Coal Mining Group is positioned in Zoucheng City of Shandong, and is the largest well mining in China at present with 7 million of annual coal yield. The 712 team in the first tunneling region of the mine adopts the gangue drainage manner similar to the program four in a main tunnel which is 5.5m in width X 4.8m in height; two ZWY120 crawler-type mucking loader and SS25 shuttle mining cars are used. Dongtan Coal Mine is firstly used crawler-type mucking loader in china, that the crawler-type mucking loader are used for developing large section gangway under vertical shafts by cooperating with large shuttle mining cars; the monthly footage is 171m, and a new situation for rock gangway fast tunneling is also developed. Gangues are removed completely after the full face is exposed, and the time for removing gangues once is about 40 minutes.

Case Analysis Two: Lianxing Coal Mine in Xinyao County of Liupanshui in Guizhou

Lianxing Coal Mine in Xingyao County of Liupanshui positioned in Guizhou is a newly constructed private coal mine; the designed annual yield is 350 thousand tons; the main shaft is inclined at 17 degrees, the secondary shaft is 23 degrees, and the air shaft is inclined at 25 degrees; the excavation face is 3.8m in height × 4m in width; the length of each face is about 700-800m. The gangue drainage manner similar to the program five is adopted in the gangway; all the three gangways adopt the ZWY120 large gradient special mucking loader cooperative with the YCC(B)-4M3 bend side bottom dumping mine car; the bomb footage of each line is 2m; the gangues are removed by about fourteen tramcars after the exposure; when the footage way is 300m, the gangue drainage time of each line of bombs is about 100 minutes; and the maximum monthly footage is 218m.

Case Analysis Three: Zunyi Miaoxin Coal Mine in Guizhou

In the Zunyi Miaoxin Coal Mine built by the investment of Chongqing Nantong Mine Industry Co., Ltd., the main tunnel is excavated 1470m, the width thereof is 5.2m × the height is 3.8m; the gradients of other three secondary shafts are respectively 30 degrees, 25 degrees and 25 degrees; the length is about 500-700m. the main gangways adopts the gangue drainage manner similar to the program 9, wherein one ZWY150 rail type mining loader, two SB14 shuttle mining cars and two XK8-6/144 storage batteries are used; the monthly footage is 245m, which is a national record of double-forward monthly footage. Two of the three secondary shafts use the ZWY120 large gradient special mucking loader of the company to load the gangues; simultaneously, the company creates the maximum gradient of using the mucking loader on a slope in China.

Case Analysis Four: Zhangcui Coal Mine of Taurus Shares of Hebei Jizhong Energy Source Group

In Zhangcui Coal Mine of Taurus Shares of Hebei Jizhong Energy Source Group, the main tunnel is excavated 1800m. The gangue drainage manner similar to the program 2 is adopted at the section 5.0m in width × 3.5m in height; overlap jointed and cooperated with the excavator, two exposure-proof shuttle mining cars SD-14(B) are used as the gangue buffer bins and the gangue transport equipment. After the operation is carried out successfully, the monthly footage is 300m, which is a new record of the industry in China.